Hydraulic Tensile Testing Machine 200T

Hydraulic Tensile Testing Machine 200T

The basic structure of Hydraulic Tensile Testing Machine includes a high-strength main frame, hydraulic loading system, fixture system, sensor system, and control and data acquisition system. We are producing the test bed with the capacity 100T 200T 300T 600T 1000T and 2000T.

| Model: | DYWP-2000 |

| Max. Capacity: | 2000 kN |

| Overall Dimensions: | 25000mm*1800mm*900mm |

| Test length: | as requested |

| Weight: | 20000 KG |

| Data collection and analysis: | Real time display of tension displacement curve and automatic generation of test report. |

Available Language:

Description

1.Hydraulic Tensile Testing Machine

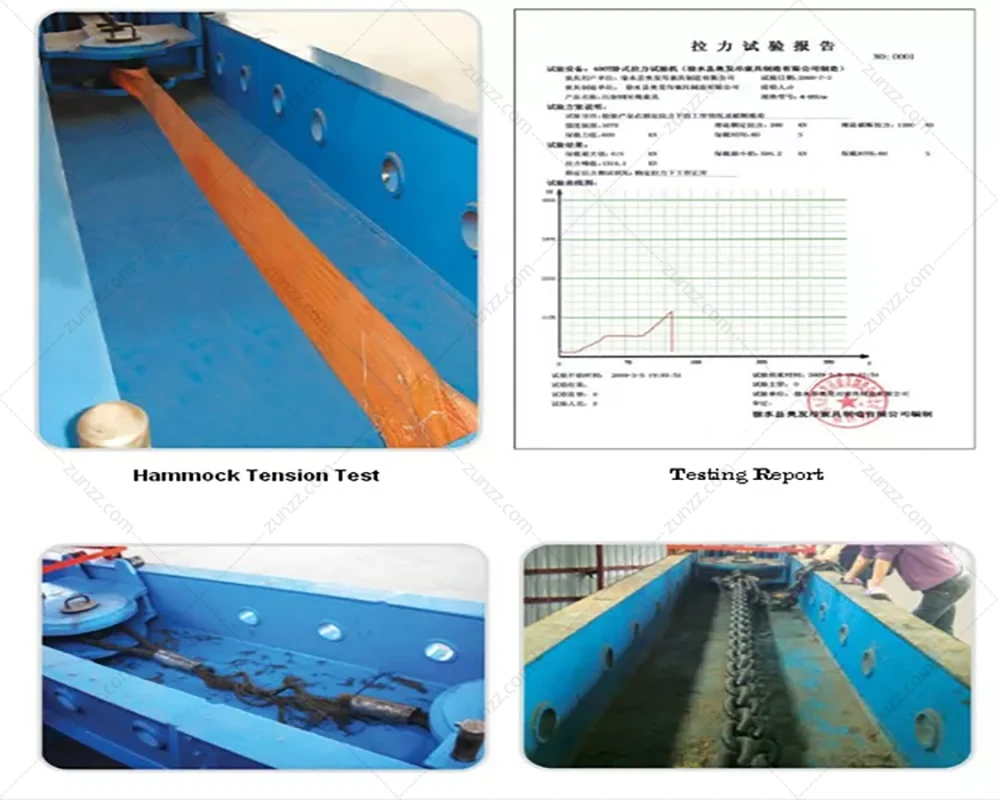

Hydraulic tensile testing machine test the wire rope, wire rope sling, webbing sling, hook, chain and so on. It is widely used in fields such as ships, construction, electricity, lifting, and rescue to ensure the safety and reliability of rigging.

The test report can be printed.

Safety Precautions: Before testing, check if the fixture is securely clamped to avoid slipping. Overloading is strictly prohibited to prevent equipment damage or personnel injury. Regularly calibrate sensors to ensure data accuracy.

major function

Tensile test: measure the maximum tensile strength (fracture strength) of the rigging.

Load testing: Simulate actual working loads to verify the load-bearing capacity of rigging.

Elongation test: Record the degree of deformation of the material under tension.

Durability testing: repeated loading to test fatigue life.

Static/Dynamic Testing: Choose different testing modes based on requirements.

2.Technical parameters

| Max. loaded pressure | 63Mpa |

| Max. Piston Movement | 1500mm |

| The pull-out speed of piston | 8 mm/sec |

| The loaded speed of piston | 2 mm/sec |

| The backward speed of piston | 10mm/sec |

| Tolerance of Pull Testing Precision | ≤1% |

| Tolerance of Displacement Precision | ≤1% |

| Tolerance of Static loading Precision | ≤1% |

| Noise Level | ≤70dB |

| Control method | Computer |

| Automatic Protect Cover | Available |

3.The advantages of the test bed

1. By using human-computer interaction to analyze and calculate the mechanical performance indicators of the tested materials, the tensile force is automatically calculated at the end of the experiment. On the basis of automatic analysis, the analysis results can also be manually corrected to improve the accuracy of the analysis.

2. Various curves such as force deformation, force displacement, force time, stress strain, deformation time, displacement time can be controlled;

3. Partial amplification of experimental curves and comparison of multiple curve overlays;

4. The control mode has automatic control mode. The automatic control is a fully digital operation servo mode, with two methods of setting test conditions: fully automatic control and human-machine dialogue programmable control.

5. Multiple uses: can conduct tensile, tear, and other tests on metal, non-metal, and components. It can meet various test method standards such as ISO and GB.

6. The oil source adopts a silent design, which is environmentally friendly and user-friendly, reducing energy consumption, reducing heat generation, and protecting the oil circuit;

7. The use of high-speed, high integration, powerful control, data processing capabilities, and high reliability is unmatched by testing machines using other processors.

Please contact us for more details, we will reply you within 24 hours

Reviews

There are no reviews yet.